over 20 years experience

Backed up by our in-house precision measuring equipment including a terrestrial laser scanner and portable coordinate measuring machine (CMM); no job is too big or too small.

We service anywhere in Australia and have also travelled to numerous overseas locations.

Call anytime to discuss your project requirements.

Our Competitive Edge

Our Services

3D Laser Scanning

Dimensional Inspection

Reverse Engineering

Aerial Inspection

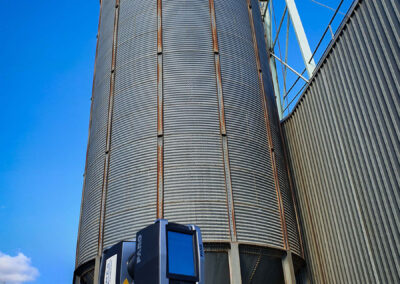

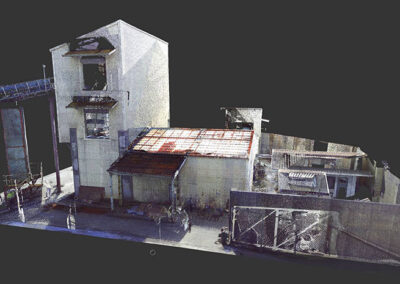

Terrestrial 3D Laser Scanning

Terrestrial laser scanning uses a ground-based laser that “paints” surfaces with millions of points, that are then registered into a point cloud. The point cloud consists of points, each with a XYZ coordinate that is measurable, and can be used to generate surfaces and shapes.

3D laser scanning offers a fast method for documenting and capturing existing conditions of a site and/or equipment. Scanning is regularly employed for difficult to access areas on sites (eg. pipe racks, roof spaces), or large complex spaces that are difficult to measure via traditional methods (eg. Manufacturing and processing plants).

3D Laser Scanning has the following advantages:

- Maximises on-site productivity

- Design and installation risks are reduced

- Eliminates re-work and cost of reactive engineering

- Reduces health and safety risks to personnel

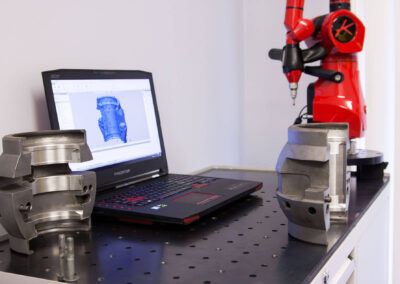

Dimensional Inspection

Dimensional inspection allows us to assess the geometric attributes of parts, plant, or equipment to verify compliance with design specifications to ascertain variances to tolerances. Common geometry checks can include hole diameters and concentricity, flatness of a surface, parallelism, position, profile, to name a few.

In basic terms a CMM probes a position in reference to a fixed point and assigns that position a 3-dimensional coordinate (XYZ). That coordinate is measurable to a high degree of accuracy, and in a controlled environment can achieve repeatability to within 0.05mm.

We have inspected a wide variety of objects that have included bearings, pump impellers, vehicle chassis, pump casings, and swirlers. In most cases clients are wanting to understand the as built condition of items to determine suitability for repair. We provide a full report detailing the inspection.

CMM inspection is particularly beneficial for items with difficult to measure geometry, or larger items that cannot be easily measured using conventional methods.

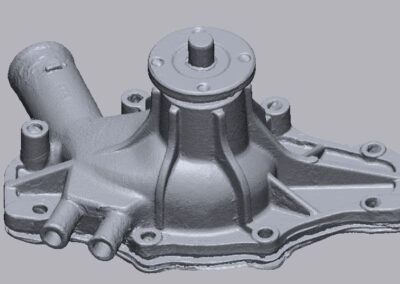

Reverse Engineering

The great advantage of reverse engineering is the designer does not need to start from scratch. We take the existing part and work backwards to arrive at a 3D CAD model and/or set of drawings. The process is much faster and allows us some flexibility in modifying the design for improvements.

At AMKS we utilise our 3D Laser Scanning equipment to capture the as-built condition of the part where it is then processed through our 3D CAD software to create the 3D model and drawings.

We can customise a solution that suits your specific requirements and have the capability to supply anything from basic point cloud data right through to complete fabrication drawings.

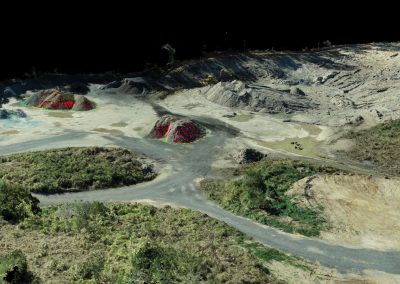

Aerial Inspection

With the latest technology in high quality cameras, we can capture more detail than ever. We can provide you with photos, video footage, thermal images, 3D surface models and terrestrial mapping.

Imagery is a great way to document changes in your worksite and provide you with an overall snapshot of what is happening beyond your reach on the ground. We can identify damage to areas that are not visible to the eye and help identify hazards such as loose objects, damage to roofs, or faults in machinery. An optional AMKS tailor-made inspection report alongside the footage obtained in your aerial inspection, can provide you with recommendations backed by an experienced engineer.

AMKS also offer thermal imagery. Thermography is a precise way to highlight damage and risks, by identifying heat leaks and gauging extreme temperature changes without the need for lengthy inspections. It is the future of inspections and a great tool to use.

By using UAVs, you have an opportunity to inspect great heights without the need for excess manpower and time. It is safer, faster, and a more thorough way to inspect your worksite.